Internal Floating Roof Tank Fire Protection

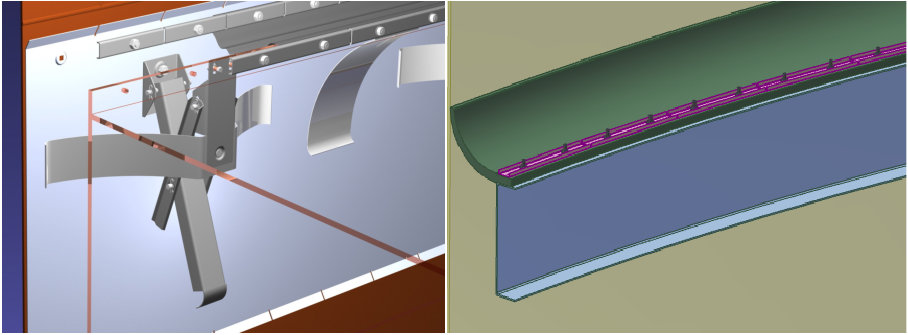

Floating roof tanks are commonly protected against lightning ignition by bonding the floating roof to the seal shoes at no less than 3m 10ft intervals use of insulating sections in the hanging linkages covering sharp points on hangers with insulating materials and installation of electrical bond straps across each pinned hanger joint.

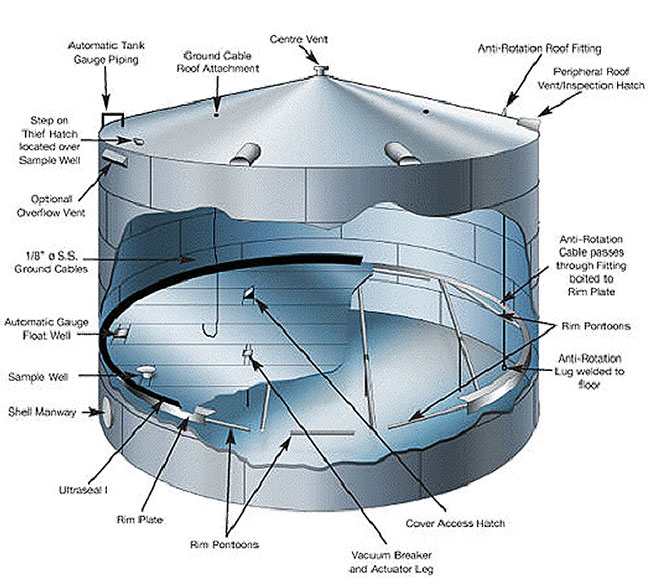

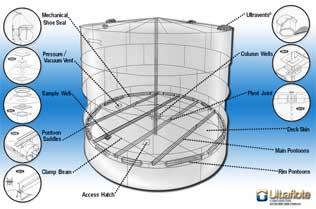

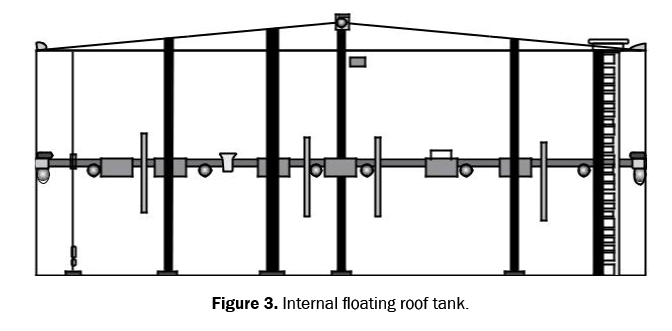

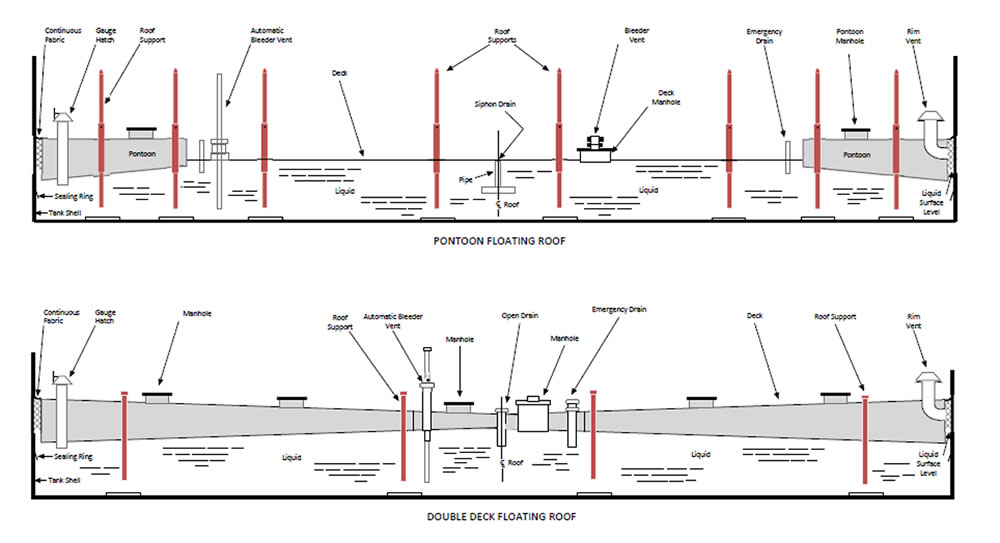

Internal floating roof tank fire protection. The roofs help minimalize evaporation losses as the liquid levels change inside the tank. Foam system the most effective method to control a fire. The contents of the tank fix the foam application rates that range between 4 liters m2 min to 12 liters m2 min. For the double deck or pontoon internal roofs of steel construction a design for sealed area protection may be permitted same as open floating roof tanks.

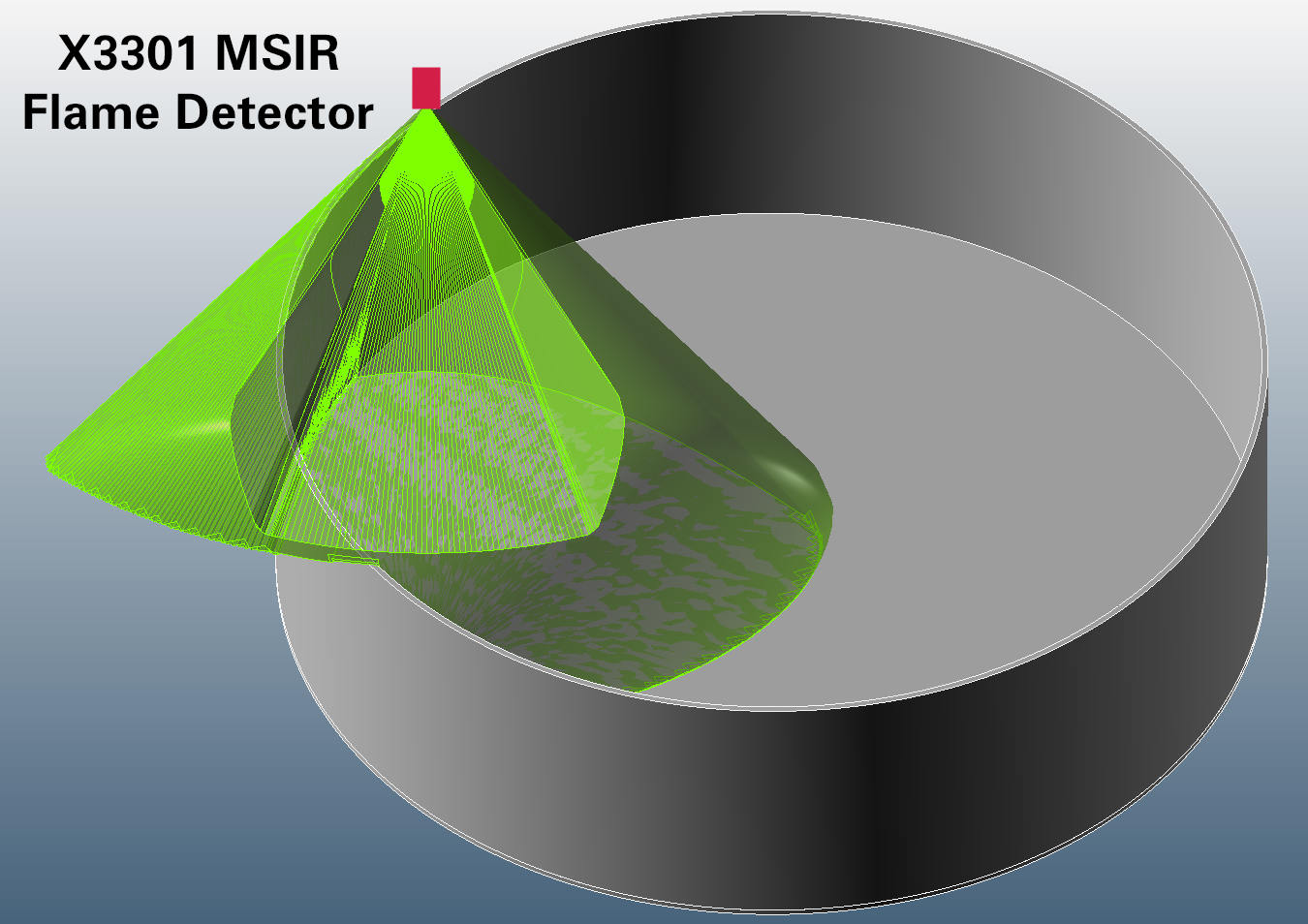

If the internal floating roof is other than a steel double deck or pontoon type the fire protection system should be designed for full surface fires similar to cone roof tanks. The lightning ignites the vapors which then catch fire. This rim seal area is prone to many hazards such as lightning and sparks produced by friction or static electricity. This presentation will focus on floating roof tanks as they are the most common and recommended tank type for crude storage.

54 external and internal floating roofs in storage tanks include different types of rim seals that allow the movement of the floating roof against the tank shell. By floating on the fuel surface the roof helps to minimise vapour loss. Rim seal unit on a floating roof tank sa fire protection is an oem of rim seal fire detection suppression solutions for the protection of floating roof tanks. Cfi rim seal fire protection for floating roof tanks external and internal floating roofs in storage tanks include different types of rim seals that allow the movement of the floating roof against the tank shell.

Lightning strikes are the culprits for most fires at storage tanks with floating roofs. The solutions available are several and each one is designed to cope with a specific tank seal design fuel content and environmental condition. Shells fitted with internal floating roofs that rise and fall as the liquid level in the tank changes. No protection rely solely on passive not generally recommended type ii systems semi fixed requires support of foam apparatus fixed manual or automatic.

The rim seal fire suppression systems are available based on the following extinguishing agents. These include specifications of foam delivery layout rates and spacing. Beneath the roof joint can identify this type of tank. For providing tank fire protection.

This rim seal area is prone to many hazards such as lightning and sparks produced by friction or static electricity. This in turn helps prevent fires.