Internal Floating Roof Tank Legs

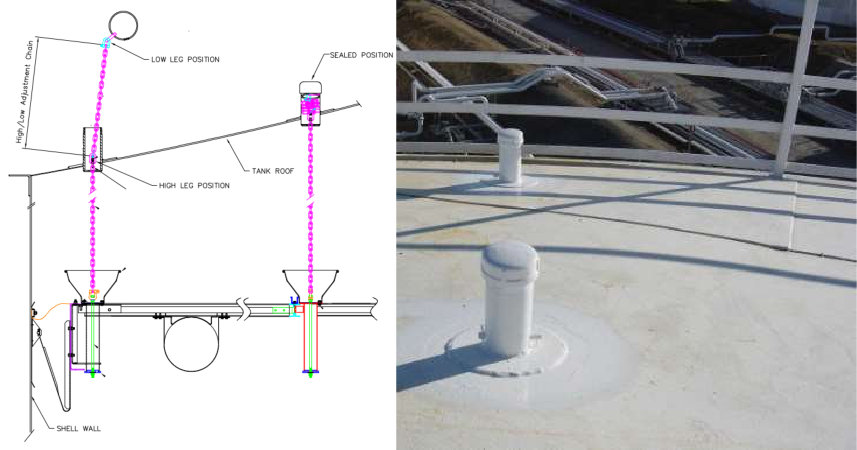

In the picture above the legs have been pulled up and pinned in the low legs position.

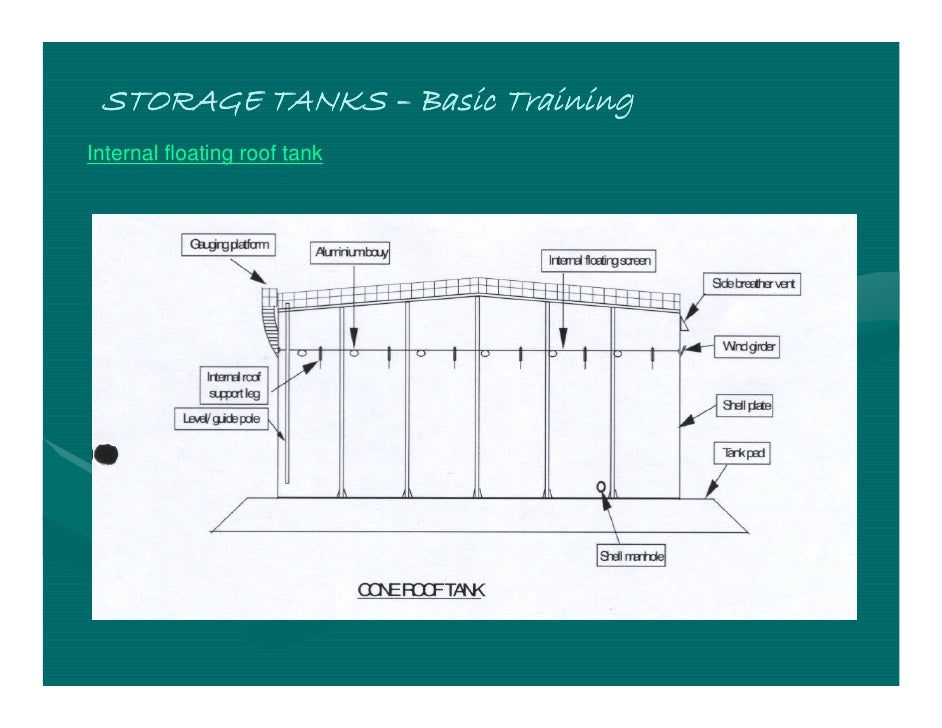

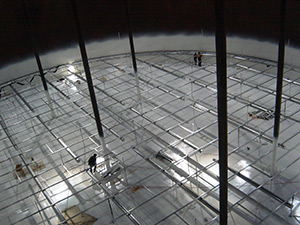

Internal floating roof tank legs. At low liquid levels the roof eventually lands and a vapor space forms between the liquid surface and the roof similar to a fixed roof tank. Internal floating roof tank is known as internal floating roof storage tank floating roof oil tank internal floating plate storage tank and internal floating plate oil tank etc. Our maintenance teams can replace damaged legs seal weld pontoons repair leaks replace your outer rim and more. The roof has support legs hanging down into the liquid.

Specifically it is an environment friendly and economical storage tank or oil tank installed a floating roof under the vault of the tank usually made of aluminum stainless steel or other material to prevent the. The floating roof must be provided with landing legs that are designed to support the external floating roof under a uniform design load of at least 25 psf api 650 appendix c 3 10. Mesa etp floating roof support leg boots are made of mesathane 6036 laminated thermoplastic urethane tpu material. The interior and exterior of the floating roof support leg boot work together to provide resistance against product loss as well as environmental effects from outside the tank.

The roof leg is pinned through the sleeve in this position prior to landing the roof to do maintenance inside the tank. For more than four decades advance tank has repaired and installed internal and external floating roofs that range from 15 to 300 in diameter. The picture above shows an external floating roof with the roof legs in the high position in this position there is typically about 6 of space between the floor and roof. The support legs are usually retractable to increase the working volume of the tank.

Leg length normally provides at lease 6 0 of clearance between tank and the underside of ifr sheeting for maintenance purposes.