Inverter Roof Ballast

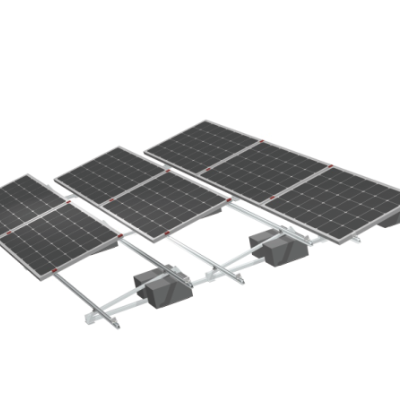

Each kit includes 4 mounting feet plus hardware to install an inverter under a rooftop array.

Inverter roof ballast. It s an enconomic method for extracting the long term performance and cost savings from the inverted roof design with anticipated lower upfront material costs. Compatible with all major pv inverter brands ecomount is compatible with all major inverter brands and meets the requirements of nearly any project. Inverted roofs are designed with the waterproofing layer usually a liquid applied membrane beneath the insulation. In this next section we will explore the why behind this.

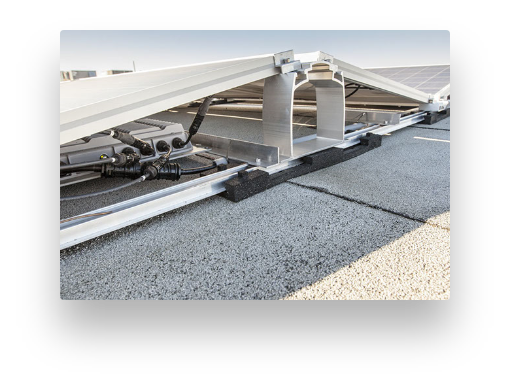

Outback proharvest offers a ballasted non penetrating rooftop mounting solution for outback proharvest truestring commercial inverters. Stone ballast typically requires crushed graded stone placed over a stone filter sheet rolled out over the insulation. Insulation boards are loose laid on top of the membrane and then weighted down with paving slabs or gravel ballast. Contact hydrotech for specific installation guidelines.

In an inverted ballasted roof the insulation boards are then placed over the waterproofing. Needed at perimeters and at large penetrations. Streamline logistics for small and large projects. You ll note that we recommend an open jointed ballast system in conjunction with an inverted roof construction.

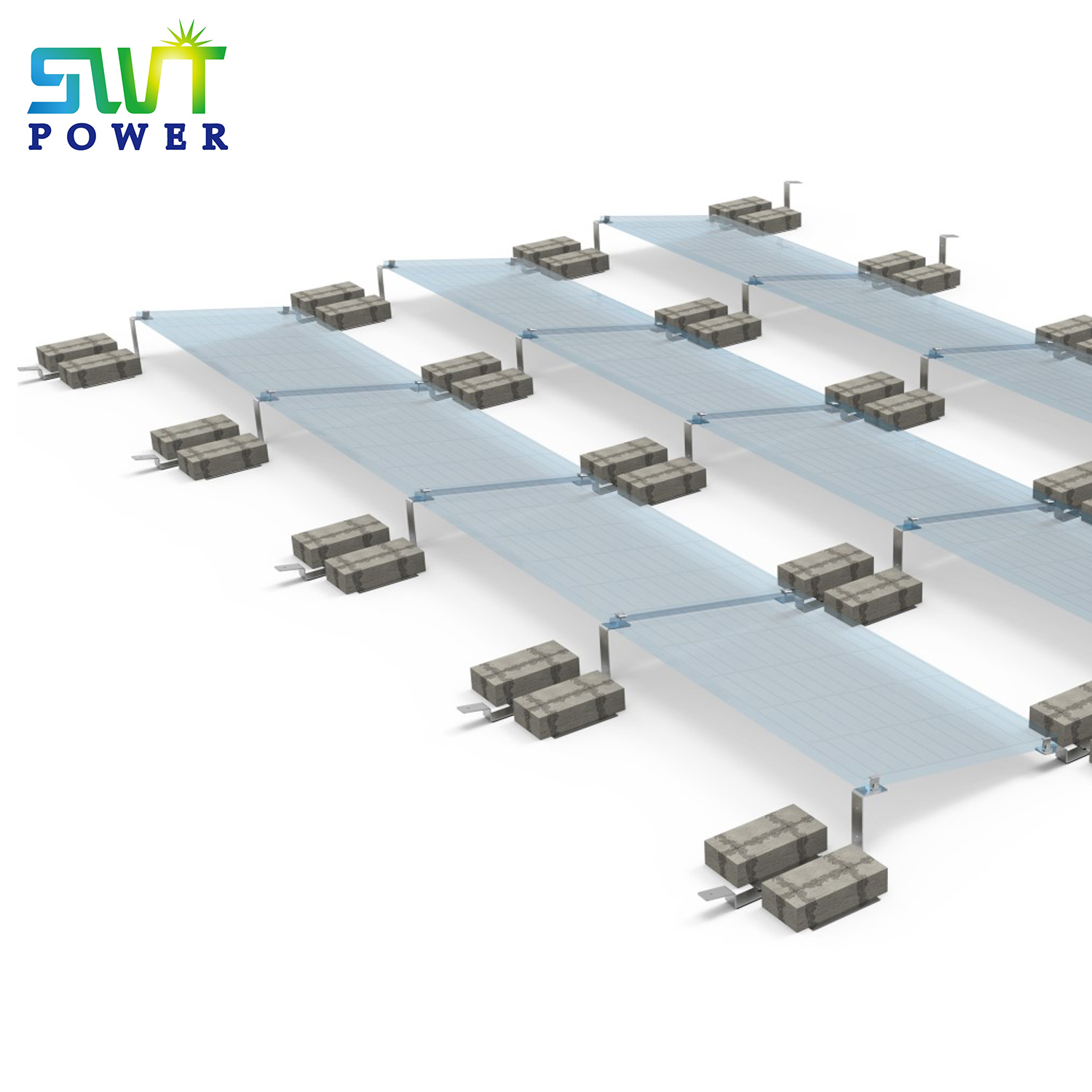

In the field of the roof a minimum of 10 lbs s f. Just like in residential solar designers must first verify that the roof can accommodate the weight of a solar array. Aerocompact a leading ballast racking manufacturer offers a free online design tool that incorporates historical wind speed snow load data and parapet height to generate a precise ballast plan for your local authority having jurisdiction ahj. Ballast roof ballast roofs are your typical inverted roof but using gravel to hold the roofing components into place.

Outback proharvest mnt ts1 01 ballast roof mounting kit. Ballast is required with 20 lbs s f. Inverted ballasted single ply roofing systems offer an excellent solution for situations where access or recreation are a priority. Up to 5 standard 4 x8 x16 ballast blocks may be placed on each base to meet even the most demanding conditions.

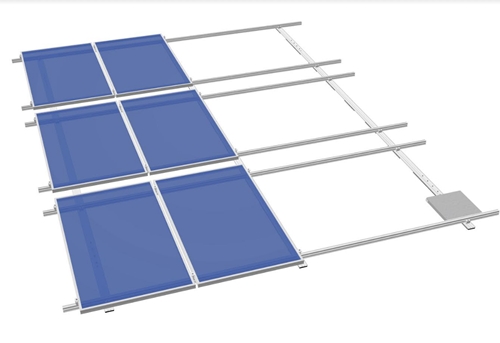

Ironridge bx delivers superior power density and design flexibility to flat roof solar arrays. Made of a glass reinforced composite the bx chassis is engineered for extreme structural loading yet is also shaped to be roof friendly and easy to install. Ballasted systems also provide maximum resistance against roof membrane damage and uv degradation protection against thermal shock fire or noise and maintain the lowest surface tem perature of all system types.