Ironridge Flashfoot 2 Roof Slope

Class a fire rated per ul 1703 with type 1 2 modules tilt mount any roof slope class a fir e rat d p r ul 1703 with typ 3 modul s tilt mount 9 5 d gree roof slop.

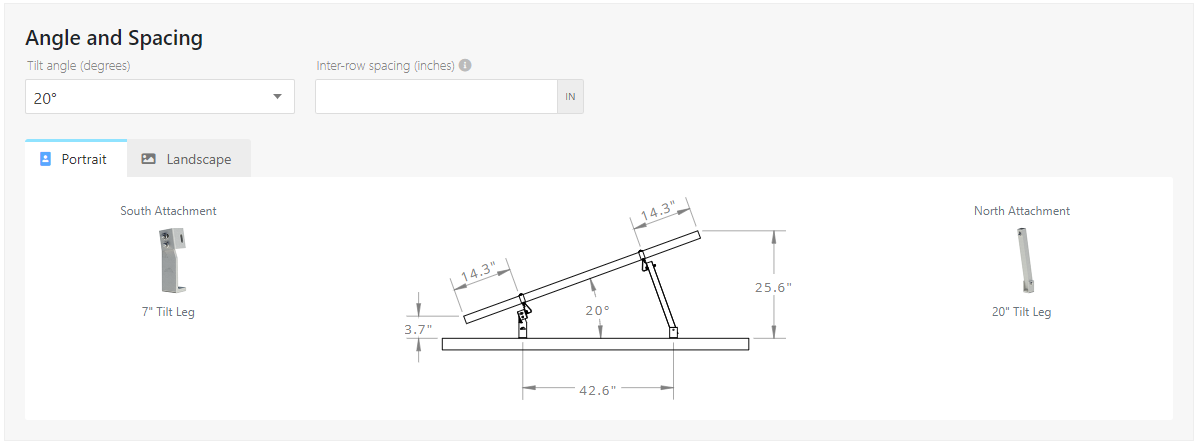

Ironridge flashfoot 2 roof slope. 5 h k attachments select the roof attachment you plan on using. What certification documents are available for flashfoot2. Low slope roofs 0 6 are extremely common in residential and commercial buildings but the roof construction and the structural system below vary significantly creating a challenge for designing solar arrays. Available in mill and black finishes.

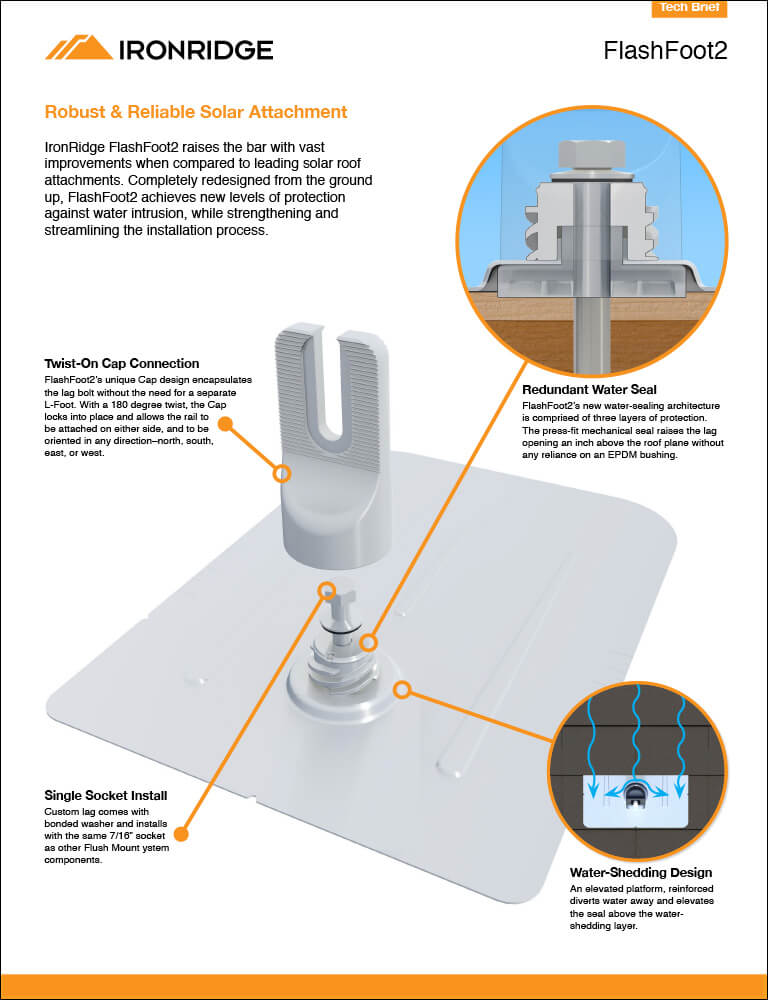

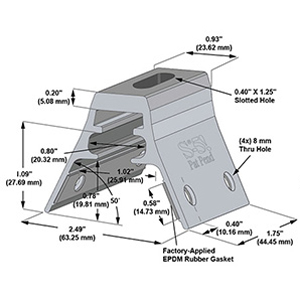

The unique water seal design is both elevated and encapsulated delivering redundant layers of protection against water intrusion. Refer to page 6 or provided manual. Flat roof attachment engineering down to the deck. In addition the twist on cap perfectly aligns the rail attachment with the lag bolt to maximize mechanical strength.

The ironridge flat roof attachment combines a high strength cast aluminum base with a 16 point fastening pattern to enable the. Flashfoot2 can be installed on composition shingle roofs with a pitch of 2 12 to 12 12 9 45 degrees. Flashfoot 2 ironridge flashfoot2 replaces separate standoffs flashings and l feet with an all in one design that incorporates both structural and waterproofing features. í visit the ironridge pitched roof resources page for more info on compatible third party attachments for different roof types.

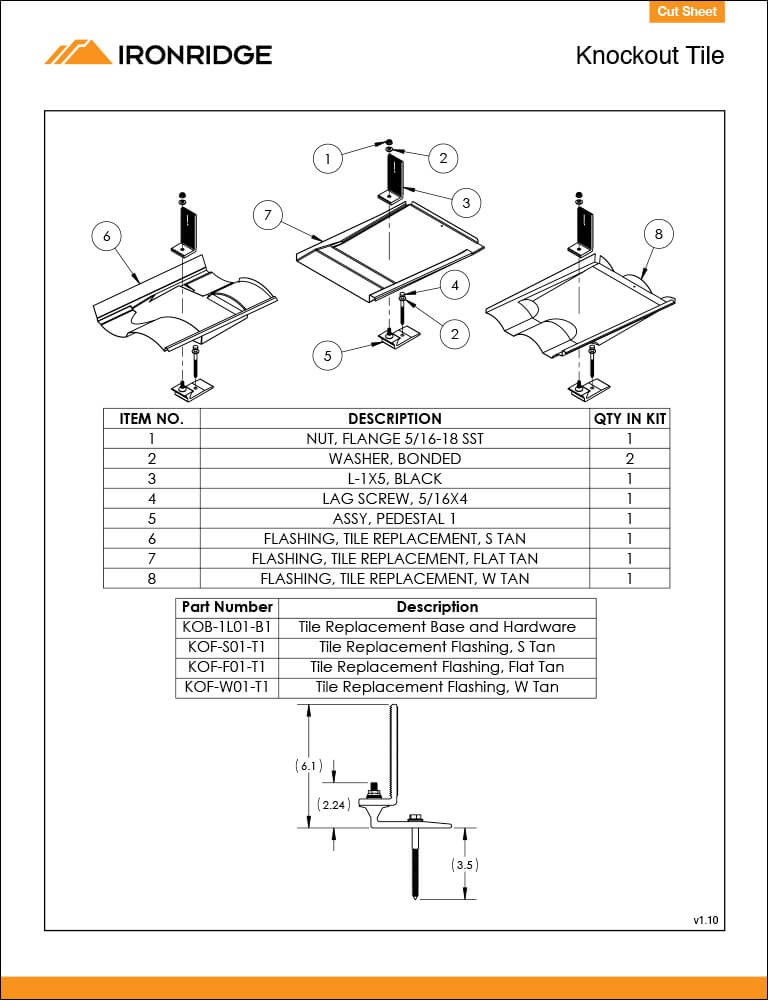

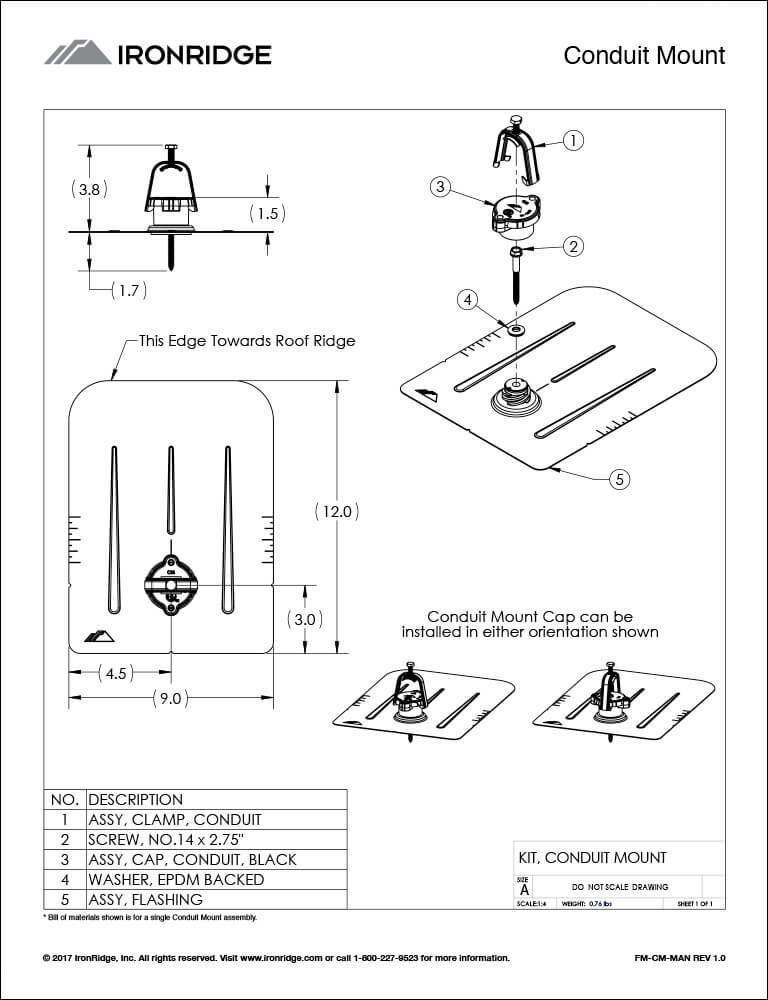

Flashfoot2 comes with a structural certification letter. Flashfoot2 is the newest addition to the ironridge flush mount system. We design and manufactures structural hardware for residential and commercial solar systems. L 2 3 4 flashfoot 2 part number ff2 0l ml ff2 0l b l l bolt lag 5 16 x 4 75 63 ft 7 16 head property material finish flashfoot2 description bolt lag 5 16 x 4 75 assy flashing assy cap washer epdm backed description flashfoot2 mill flashfoot2 black value 300 series stainless steel clear v1 21.

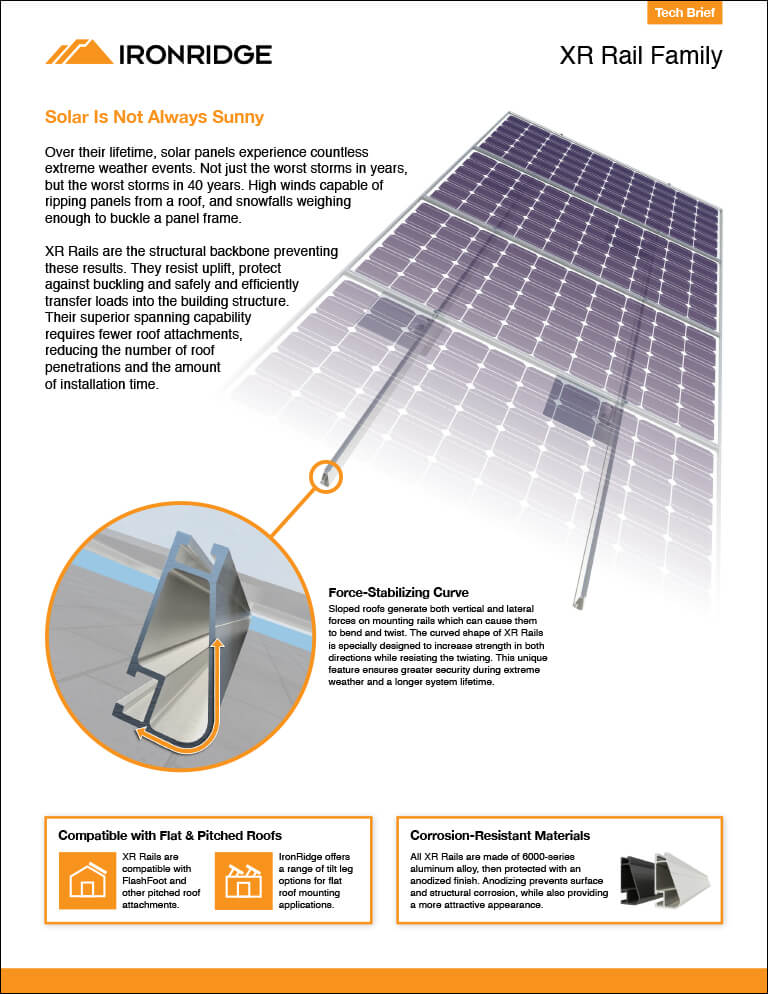

Ironridge s all in one flashfoot roof attachment is for pitched composition shingle roofs. Tighten lag bolt until fully seated. Their unique curved profile increases structural strength and spanning capability allowing for fewer roof penetrations and more cost effective system designs. Slide flashing between 1st and 2nd course so the top is at least 3 4 above the edge of the 3rd course and the bottom is above the edge of the 1st course.

3 line up pilot hole with flashing hole and insert lag bolt with bonded washer through flashing.