Is A Process Of Joining Thin Sheets Of Metal

6 types of sheet metal joining techniques.

Is a process of joining thin sheets of metal. It is slower than arc welding d. They produce permanent joint between the parts to be assembled. Lcmc152orakdp lcmc152orakdp 10 30 2017 german middle school 5 pts. Sheet metal processing belongs to the forming process the material utilization rate is high and the quality is light the strength is good and it is beneficial to electromagnetic.

300 c to 350 c for soft soldering. It is used to join different material and sheet thickness parts. They are mainly used to assemble many parts to make a system. Rivets are used to form solid strong and permanent bonds.

Advantages of clinching joints. Sheet metal clinching joint creates a button type positive connection between two or three layers of sheet metal. Sheet metal usually refers to a thin metal plate with a thickness of 6 mm or less. Welding is a metal joining process in which two or more parts are.

The temperature required is approx. Clinching is characterized by a series of advantages over competitive technologies. ø can be used for thin sheet metal sections. Soldering solder is an alloy of tin 63 lead 37 60 40 solder melts at 361 f soldering is metal joining process in which the filler metal or alloy is heated to a temperature below 450oc and melted only filler metal melts and deposits fusing the workpiece.

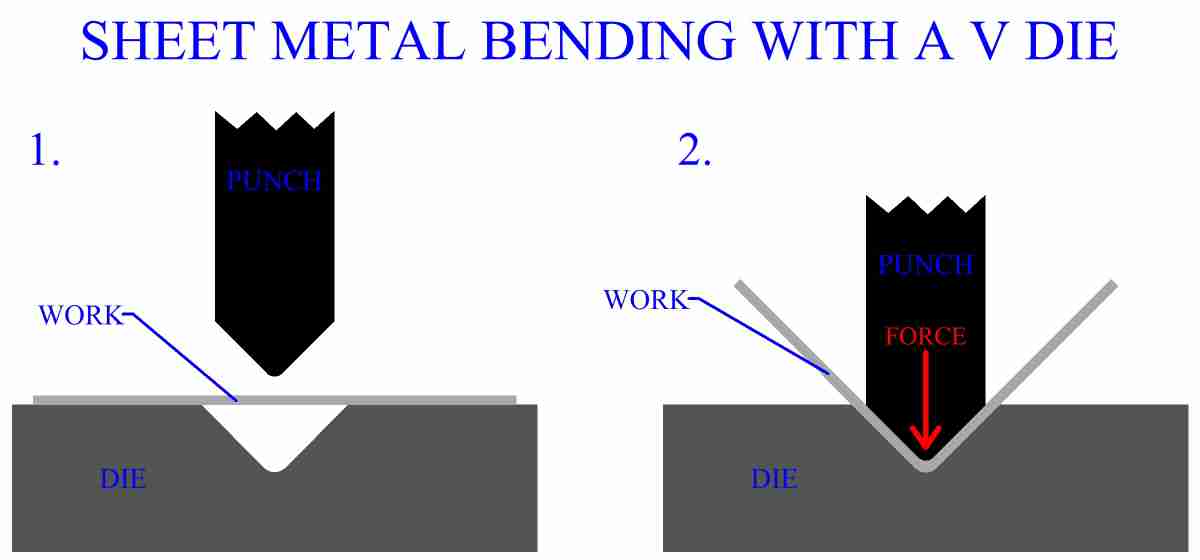

It is suitable for thin sheets c. Sheet metal fabrication is a cold processing process which is commonly used for punching bending drawing and forming. The joining process can be used with dissimilar materials and it can be used with different thickness materials. Clinching or press joining is a bulk sheet metal forming process aimed at joining thin metal sheet without additional components using special tools to plastically form an interlock between two or more sheets.

Appliance engineers have several options for joining sheet metal including screws rivets welding bonding clinching and folding. Joining includes welding brazing soldering adhesive bonding of materials. For sheet metal parts the thickness is the same everywhere. There are safety problems in storing and handling the gases.

The process of joining two pieces of metal with a different fusible metal applied in a molten state is called as a. Weld studs can. Soft soldering is a processes of joining two or more pieces of similar or dissimilar thinner parts by an alloy called solder which has a lower melting point than the base metals. Riveting is often the technique used in heavy sections as well such as boilers bridges tankers etc.

The process is generally performed at room temperature but in some special cases the sheets can be pre heated to improve the material ductility and thereby avoid the formation of cracks during the process. They cannot be separated easily by application of forces. Riveting is the process of joining metal pieces together by using mechanical fasteners. Out of all the techniques riveting perhaps is the most difficult one to carry out.