Iso Class 7 Clean Room Specifications

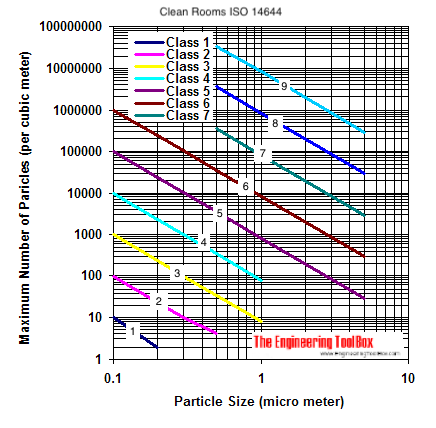

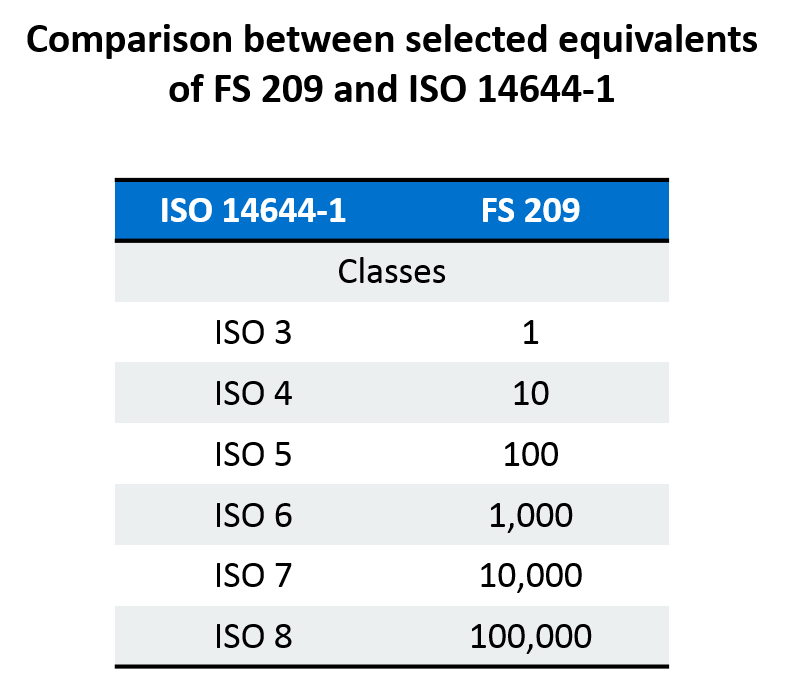

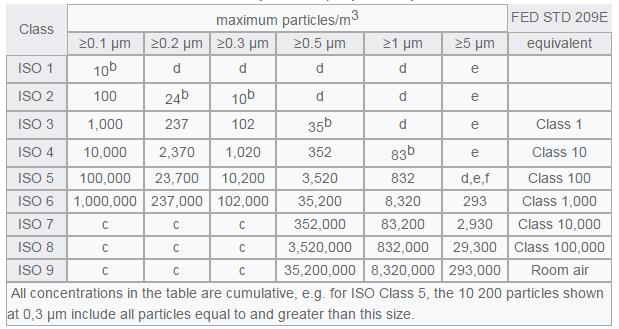

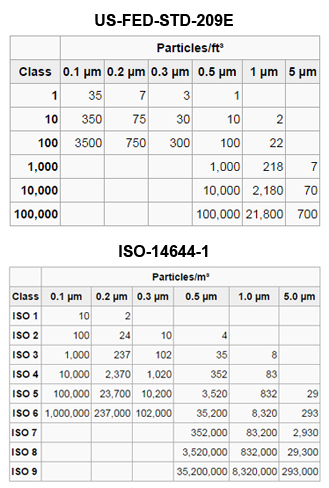

Iso 14644 1 and older standard fs 209e determine class by the concentration levels of particles.

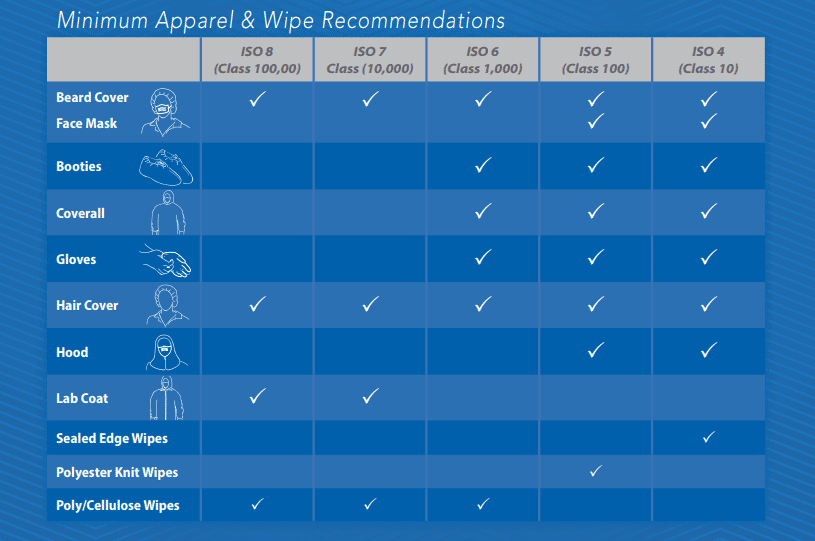

Iso class 7 clean room specifications. However a full coverall is sometimes used with open wrists and ankles or with elastic wrists and ankles. Iso class 7 clean rooms were previously defined under us federal. Only particle populations having cumulative distributions based on threshold lower limit particle sizes ranging from 0 1 µm to 5 µm are. Iso 8 is the starting cleanroom level.

And separative devices as defined in iso 14644 7. Information on iso 14644 1 2015 class 7 cleanroom classification. What exactly is cleanroom classification. See the maximum allowable concentrations by cleanroom class on our cleanroom classifications page.

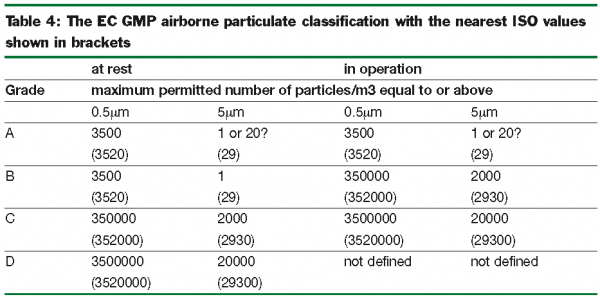

This part of iso 14644 specifies the classification of air cleanliness in terms of concentration of airborne particles in cleanrooms and clean zones. Cleanrooms are rated based on the number of particles they can handle. Class 10 000 associated eu gmp grade. Iso 7 is a common clean cleanroom classification.

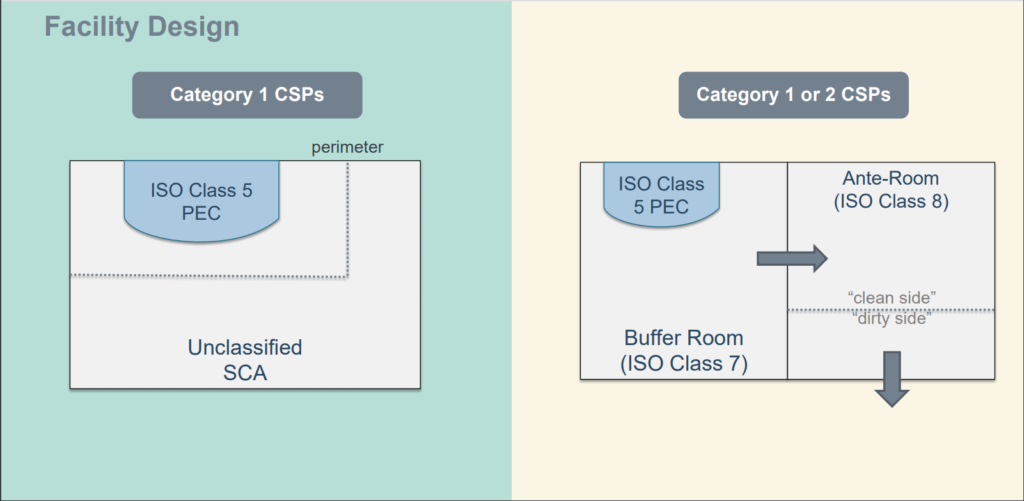

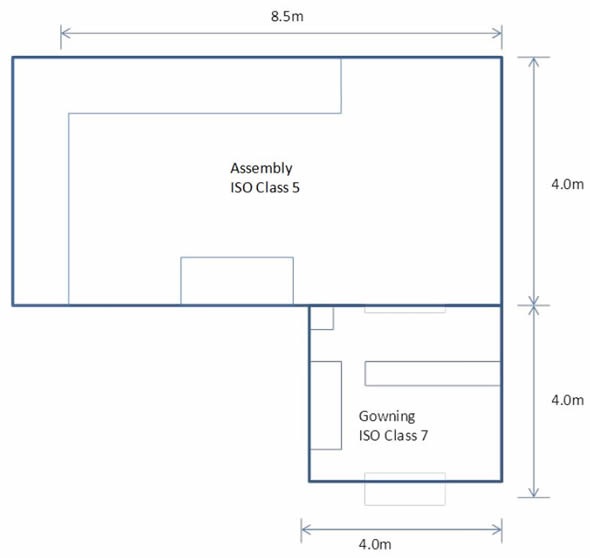

In a class 10000 iso 7 cleanroom. Iso 6 cleanroom class 1 000 in theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image. The particles range in size from 1 5 microns µm. A cleanroom must have less than 352 000 particles 0 5 micron per cubic meter and 60hepa filtered air changes per hour.

In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock. Federal standard 209e equivalent. Clean room classification iso class this refers to the level of cleanroom particulate cleanliness based on a number of airborne particles of a certain size per cubic metre. Iso 7 cleanroom standards.

The current accepted standards for cleanroom classifications are iso international standards organization standards. The international standards organization is recognized worldwide. 60 90 for iso 7 cleanrooms organisations typically measure micron sizes 5 0µ and 0 5µ. Classification for cleanrooms ranges from iso 1 to iso 9 with iso 9 being the dirtiest and iso 1 being the cleanest these classifications are assigned based on the maximum allowable concentration of particles per cubic foot or meter of air.

The class defines a minimum cleanliness level not a specific design. This is the classification system most widely accepted internationally and the u s. C recommended air changes per hour ach. Just switched to this standard officially in 2001.

The equivalent fed standard is class 10 000 or 10 000 particles per cubic foot.