Jb Weld Epoxy 50112 Good For Sheet Metal

Panel adhesive is for plastics and other materials that flex.

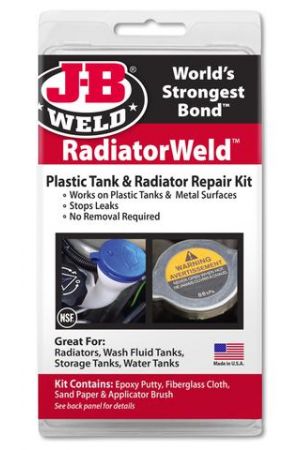

Jb weld epoxy 50112 good for sheet metal. J b weld is the original cold weld two part epoxy system that provides strong lasting repairs to metal and multiple surfaces. J b weld original can be used to repair many different materials including metal wood plastic ceramic fibre glass brick concrete and much more. That is only 30 the strength of a good steel weld. Jb weld j b weld vs loctite vs devcon vs quiksteel vs gorilla also watch my j b weld fail.

Mixed at a ratio of 1 1 it forms a permanent bond and can be shaped tapped filed sanded and drilled after curing. Then 5mm would be close to 24 gauge sheet metal and it would be difficult to weld unless your one of those guys who like to weld razor blades or aluminum cans together. The key to ensuring you have the strongest bond possible is the preparation of the materials to be repaired and the correct application of the j b weld. J b weld 50112 clearweld 5 minute set epoxy syringe clear 25 ml.

Available from these sellers. Because it s a two component or 2k epoxy system it uses reactive chemistry to create the strongest bond possible. J b weld has a tensile strength of 3900 psi. How to use jb weld original.

J b weld waterweld epoxy since the epoxy was 2 part putty it was easy get the epoxy to penetrate the pvc pipe in the cut area and get a good seal. The jb weld i m familiar with is metal and works on metal surfaces that don t flex. Jb weld is good stuff for sure. At room temperature j b weld sets in 4 6 hoursto a dark grey color.

A joint is only as strong as its weakest spot which in this case is 1800 psi on a good day. Regardless you would need to follow some of the advice found elsewhere for welding sheet metal spot skip welding etc. It sealed and i have been monitoring the repaired area for almost a month absolutely no signs any moisture leakage now. This jb weld review has for goal to address a different type of welding practice and products.

A clear quick setting and multipurpose two part epoxy that provides a strong and lasting bond on surfaces including metal tile most plastics ceramic glass wood and more. J b weld only adheres to the surface so the bond strength is actually only 1800 psi. When the word welding is mentioned it conjures up images of fire and metal joined together. J b weld known as the original cold weld was developed as an alternative to traditional torch welding.

It s designed to be extremely effective in even the harshest environments. It was developed in 1969 for use in cold welding the bonding process used to adhere two products together without using torch. There is a youtube video where a guy used it to cast a complete lawn mower engine head with the stuff.