Kevlar Vs Carbon Fiber Strength

Kevlar has a tensile strength of 3620 mpa and dyneema has 3600 mpa of tensile strength.

Kevlar vs carbon fiber strength. You can use carbon fiber to make the deck and other parts stronger. Kevlar aramid is used for high performance composite applications where lightweight high strength and stiffness damage resistance and resistance to fatigue and stress rupture are important. But because dyneema has a much lighter density than kevlar 0 97 compared to 1 44 it scores a higher strength to weight ratio. All the answers are pretty good.

Kevlar and carbon fiber are strong and have the capacity to provide proper protection. Carbon fiber has a significantly high compression strength but is the most expensive synthetic fiber available. It is lighter and stiffer than glass fiber and very strong. Kevlar carbon fiber hybrid a mixture of the best in both kevlar and carbon fiber this fabric combines the properties of the two fibers in each layer to deliver high strength to weight ratio high conformability impact resistance abrasion resistance dimensional stability and fatigue resistance.

Kevlar is a heat resistant and strong synthetic fiber related to other aramids such as nomex and technora developed by stephanie kwolek at dupont in 1965 this high strength material was used first commercially in the early 1970s as a replacement for steel in racing tires. The strength of both materials is similar. We offer carbon fibre in small quantities on our e commerce site sold by the metre and carbon fibre and aramid fabrics including kevlar from 10m up from our leeds and newry depots. Kevlar fiber has a tensile strength comparable with that of carbon fiber a modulus between those of glass and carbon fibers and lower density than both.

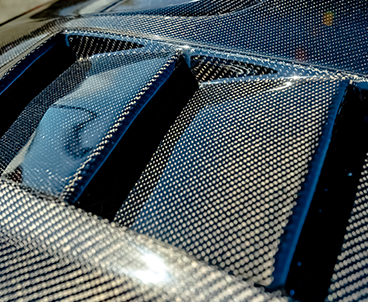

Some non brittle material distorts before breaking but kevlar carbon fiber and e glass are brittle and fail with almost no distortion. The strands are pasted in a cross positioning pattern and this helps in increasing the strength of the fiber. Carbon fiber deck test. Tensile strength is the maximum stress that a material can withstand while being stretched before if fails.

While kevlar is constructed at a microscopic level and the strands are poured in a liquid format. However as a chemist and somebody who worked on polymer science and materials i feel there are a few missing points which could help explain some of the characteristic properties of carbon and kevlar fibers.